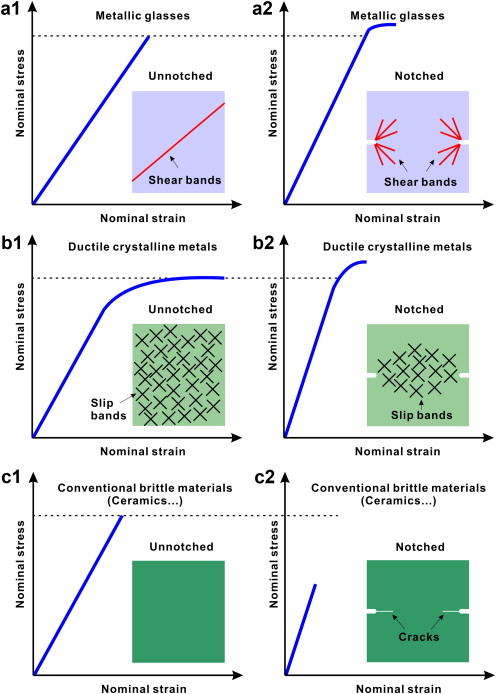

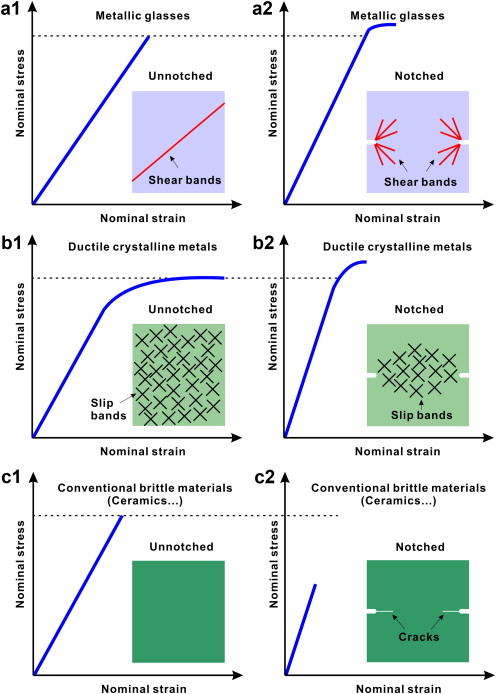

Stress strain curves for two brittle materials.

Stress vs strain curve ceramics vs metals.

The elastic deformation of a solid is a reversible process when the applied stress is removed the solid returns to its original state.

A typical stress strain profile for a ductile metal resembles the following.

Elastomers are the ones that strains more w a lower stress.

To populate the map constitutive equations are found.

Yielding starts at c and ends at d.

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

1 metals al alloy stress strain curve.

And finally analogous to ceramics are the stiff fibers and rigid plastics.

Deformation mechanism maps provide a visual tool categorizing the dominant deformation mechanism as a function of homologous temperature shear modulus normalized stress and strain rate generally two of these three properties most commonly temperature and stress are the axes of the map while the third is drawn as contours on the map.

Represents straightening of the crimped ligament fibrils.

Stress strain curve is the plot of stress and strain of a material or metal on the graph.

The stress strain curve in this part of the graph is almost horizontal which implies that there is an appreciable increase in strain for a negligible increase in stress.

1 2 typical stress strain curve of a ductile metal2 the material initially behaves in a linear elastic manner.

While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics.

2 stress strain curve for ceramics.

Stress vs strain curve.

However when the stress is high the plot passes a small jump on the axes.

With a very short elastic region but highly capable of supporting huge stresses.

A highly elastic polymer may stretch over 10 times the original length before breaking while a metal might elastically stretch 10 of the original length elastically and may stretch.

Derived from axially loading an object and plotting the stress verses strain curve.

The zone where a material will return to its original shape for a given amount of stress toe region applies to a ligaments stress strain curve.

Stress and strain are linearly related and.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

In this the stress is plotted on the y axis and its corresponding strain on the x axis.

After the point d the material due to strain hardening again starts taking load and the curve rises as seen in the.